Worm gearbox Price And Quantity

- 6000.00 - 60000.00 INR/Piece

- 6000 INR/Piece

- 1 Piece

Worm gearbox Product Specifications

- Industrial

Worm gearbox Trade Information

- Vadodara

- Cash Advance (CA) Cash in Advance (CID) Cheque

- 100 Piece Per Week

- 3 Days

- Sample costs shipping and taxes has to be paid by the buyer

- Asia

- All India

Product Description

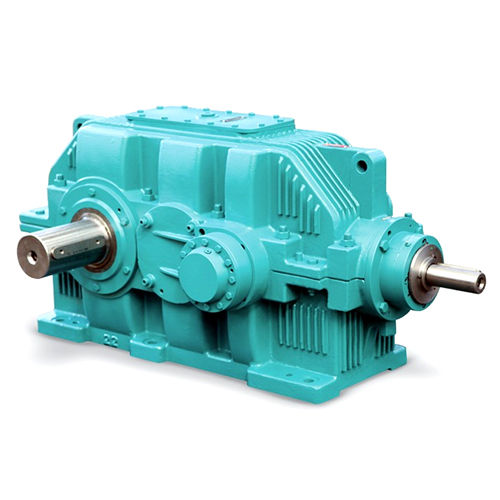

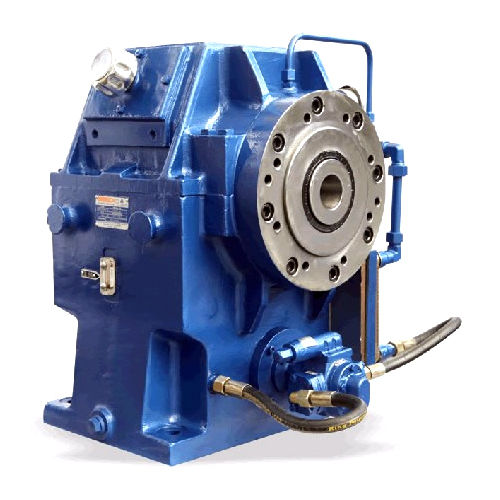

A worm gearbox, also known as a worm gear reducer or worm gear drive, is a type of mechanical gearbox used to transmit power and reduce rotational speed between two shafts that are perpendicular to each other. Here are the main components and features typically found in a worm gearbox:

Worm gearbox Supplier in India

Worm gearbox Supplier in Gujarat

Worm gearbox Supplier in Vadodara

Worm gearbox Dealer in India

Worm gearbox Dealer in Gujarat

Worm gearbox Dealer in Vadodara

Worm Gear: The worm gear is a type of gear with a threaded shaft resembling a screw. It meshes with the worm wheel (also known as a worm gear or worm wheel), which is a cylindrical gear that typically has teeth oriented at an angle to the worm's shaft. The worm gear is usually the input and the worm wheel is the output.

-

Input Shaft: The input shaft is connected to the worm gear. When the input shaft rotates, it drives the worm gear.

-

Output Shaft: The output shaft is connected to the worm wheel. As the worm gear rotates, it meshes with the teeth of the worm wheel, causing the output shaft to rotate at a reduced speed compared to the input shaft.

-

Housing (Gearbox Casing): The gearbox casing encloses the worm gear and worm wheel, providing protection and support for the internal components. It also contains lubricant to reduce friction and heat generation.

-

Bearings: Bearings support the input and output shafts within the gearbox, reducing friction and wear.

-

Lubrication System: Worm gearboxes require lubrication to ensure smooth operation and to dissipate heat generated during operation. Lubrication can be provided via grease or oil depending on the application and operating conditions.

-

Housing: The housing of a worm gearbox is typically made of cast iron or aluminum alloy, providing durability and strength.

Worm gearboxes are commonly used in applications where a large reduction in speed and high torque transmission is needed, such as in conveyor systems, packaging machinery, lifts, and certain automotive applications. They offer advantages such as compact size, high torque transmission capability, and the ability to hold loads when not actively turning (self-locking feature due to the nature of the worm gear design). However, they may have lower efficiency compared to other types of gearboxes due to friction losses in the meshing of the worm gear and worm wheel.

Other Products in 'Industrial Gearbox' category

GST : 24BEJPP3123F1ZS

|

|

SRI ENERGY TECH CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |